Yoshinori Kuroyanagi

Born in Nagano in 1947, Yoshinori Kuroyanagi joined Tsutatomo Printing Co., Ltd. in March 1963. He is a printer who finishes printed materials that require advanced technology with expert skill. He has been with the company for 59 years. His hobbies include drinking, smoking, and sometimes fishing.

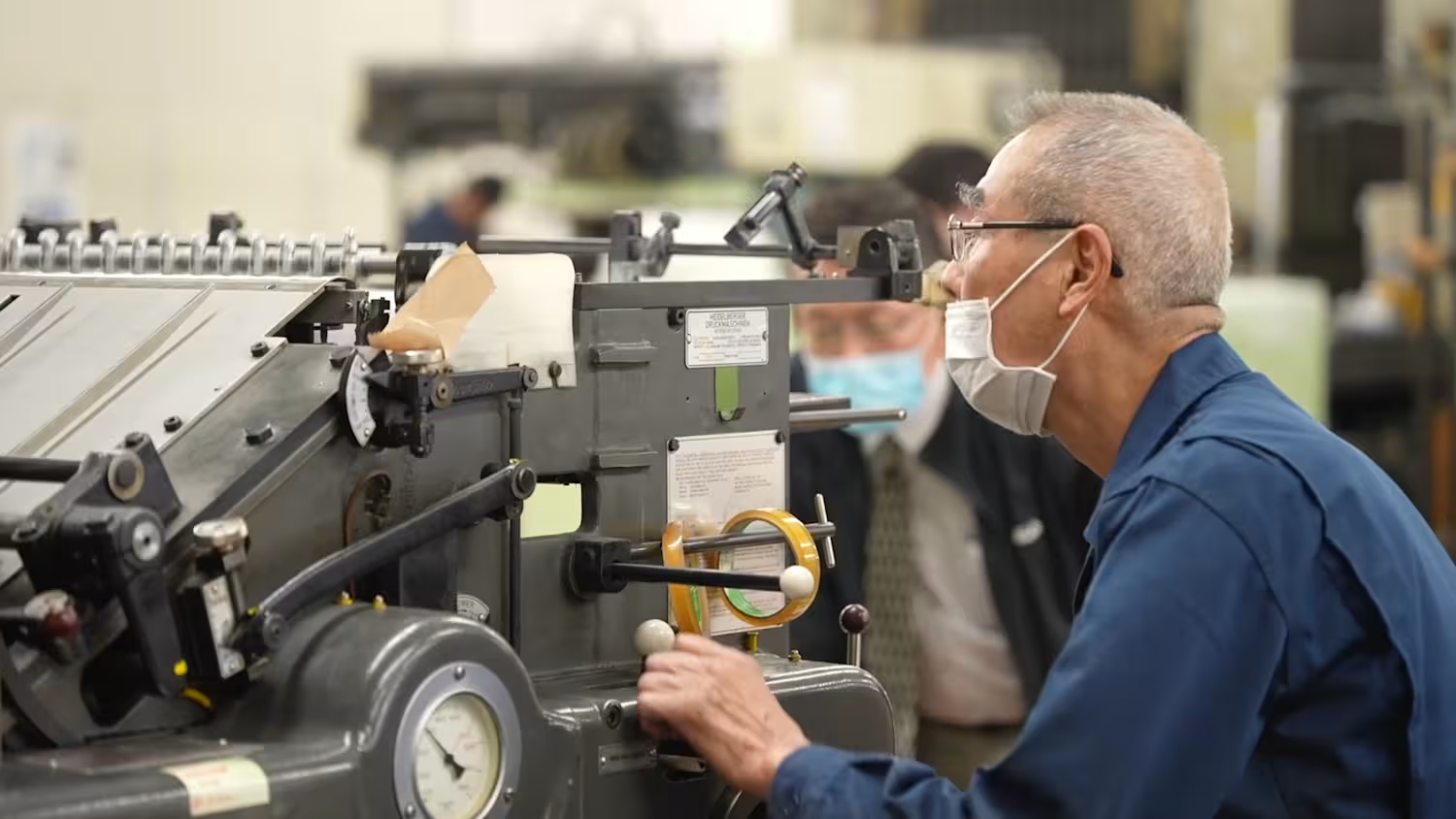

Masao Takaoka

Born in Tokyo in 1957, Mr. Takaoka joined his father's company, the Kazui Press in 1982, and has served as Representative Director since 1995. He is a Fellow of the Royal Society of Arts (RSA), a Tokyo Meister (outstanding engineer) certified by the Tokyo Metropolitan Government, a "Master of Techniques" certified by the Shinjuku Monozukuri Meister, and an advisor to Monotype.

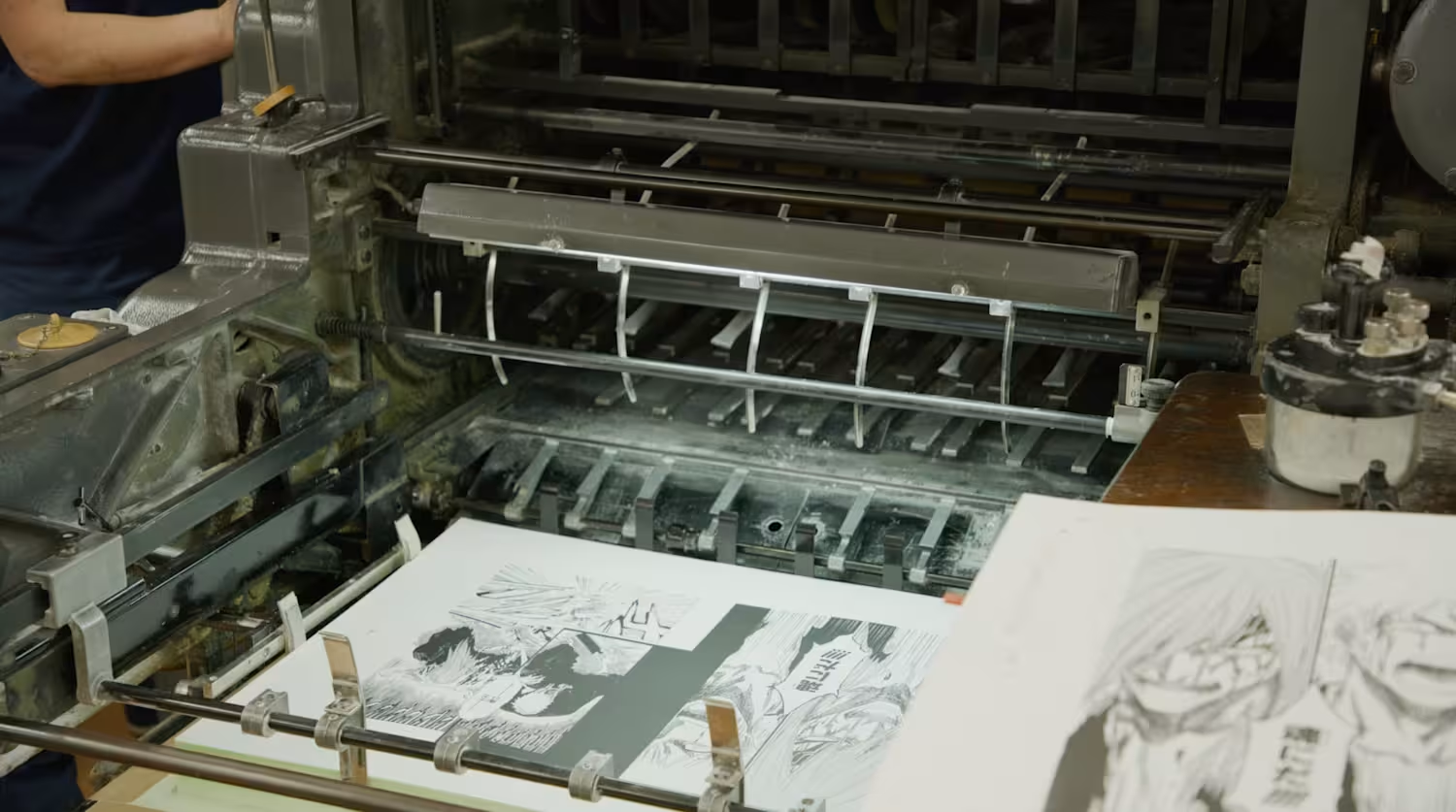

A Heidelberg letterpress that has been in operation for over 60 years

Masashi Okamoto (SMAH), Shueisha Manga-Art Heritage: I have visited here (Tsutatomo Printing) once before, but there were so many things I did not understand when I saw the letterpress printing process. This time, I am with Mr. Takaoka, an expert in letterpress printing, hoping that he will be able to tell us about how the printing of manga art differs from regular printing, as well as the history of letterpress printing.

I received a brief profile of Mr. Kuroyanagi in advance, and it seems that you and Mr. Takaoka are 10 years apart in age.

Masao Takaoka of the Kazui Press: I am turning 65 this year.

Yoshinori Kuroyanagi of Tsutatomo Printing: Is that so?

SMAH: I would like to start by asking about your background, Mr. Kuroyanagi. Were you born in Nagano Prefecture?

Kuroyanagi: Yes, I was. I was born in present-day Iizuna-cho in Kamiminochi-gun. Back then it was called Mure-mura.

SMAH: Is it near here?

Kuroyanagi: It's about 25- or 30-minute drive by car.

SMAH: So, you were born there, and was Tsutatomo Printing your first job?

Kuroyanagi: Yes. I started in March 1963, right after graduating from junior high school. My schoolteacher suggested that I go into printing.

SMAH: Were you originally interested in printing?

Kuroyanagi: No. I wasn't interested at all, but I couldn't think of any other type of work. Just as I was about to enter the company, I had a classmate who I got along well with, and he said, "Okay. I've decided to come here," so that's what happened. I didn't really think about anything too deeply (laughs).

SMAH: I understand that there was a factory at a different location from this one at that time and almost all the printing machines were letterpresses.

Kuroyanagi: That's right. There were many old fanning-type printers (machines with a device for feeding printed sheets of paper to a receiving board through a fanning motion of the tailboards arranged in a comb-like pattern at the back) in the old days of typography, and we mainly used those machines. There were also machines with automatic feeders that replaced the manual feeders that fed one sheet at a time into the machines. At the time I joined the company, there was already a Heidel (a printing machine made by Heidelberg in Germany). After that new machines were added and others were replaced. At the most, there were eight machines in operation at the same time.

SMAH: Is the machine that's here now a new one that wasn't here when you first joined?

Kuroyanagi: No, we still use the one that we had back then.

SMAH: So, that machine has been running longer than you've been working!

Kuroyanagi: Yes, yes, the machine is more senior than I am. (Laughs)

Takaoka: Do you mean that the Heidel was used along with the letterpresses from Sakurai Seisakusho? That's quite early!

Kuroyanagi: I think we had 16 machines total.

SMAH: I guess you mean eight Heidel machines imported from Germany and eight Japanese letterpresses. Did the machines run from morning till night? Did you have a two-shift system at that time?

Kuroyanagi: We never had two shifts. We worked overtime at night until 10:00 p.m., and when we finished, we would go home.

SMAH: What time did you start in the morning?

Kuroyanagi: 8:30 am.

Takaoka: That used to be rather normal. (Laughs)

SMAH: Just today, I was asking about the time Mr. Takaoka's father (Juzo Takaoka) started printing on the letterpress. When I observed you earlier, I think you were inserting blank paper between sheets of printed paper, which is exactly what he did as an apprentice. Mr. Takaoka told me that this kind of work is not done anywhere else.

Kuroyanagi: I came up with that idea myself. A lot of pressure is applied when printing on paper.

Takaoka: The ink is too thick and can be seen from the back of the paper.

Kuroyanagi: That's right. Sprinkling powder is meant to prevent the ink from showing through but does not work well. In the past, we used to use it for print material such as the seating order for weddings made on thick paper, but I was asked to stop using the powder. This is because a guest wearing dark clothing would find his clothes turn would white if he held the powdered printed seating arrangement. However, if you do not use this technique, the print shows through on the backside of the paper. After thinking about it, I decided to place an extra sheet of paper between each printed sheet. (*This process is called kanshi-ire, meaning to insert paper.)

SMAH: Mr. Takaoka, you said your father did a similar type of work during his apprenticeship.

Takaoka: That was before the war. It is the first role of an assistant to insert newspaper into the fanning machine (for that type of printing press). At that time, there was no automatic feed, so they were still feeding paper in manually, and my father used to insert the paper into the other side of the machine. Back then, there were no fancy powders available, so if you did not manually insert the paper, you would end up with print showing through on the back.

The largest resin plate we've ever seen

SMAH: We were just talking about the prewar period, and the historical story that Mr. Takaoka told us during the tour was really interesting. ...... As we watched Mr. Kuroyanagi applying double-sided tape to the back of the resin plate, he said, "It was really hard work before we had something as convenient as double-sided tape. Did you have to nail down the zinc plates?

Takaoka: We used to have to nail the zinc plates to a wooden board to fix them in place and hang them on the machine so they would be aligned with the height of the typeface.

Kuroyanagi: We had these thin, very short nails called lead plate nails. That make it easier for the nails to go in. We drilled holes into the zinc plates, then hammered the nails into place to secure them. Then, we could print.

SMAH: Is that how it was done when you first started working?

Kuroyanagi: Yes. Then came (metal) base plates and double-sided tape. However, this is the first time I have worked on a large resin plate like this one. By working on this project it was the first time I touched such a large resin plate. So at first, I thought it would be impossible to do something like this. ......

Everyone: (Laughs)

Kuroyanagi: Well, it was quite difficult.

SMAH: Thank you for your hard work.

Kuroyanagi: When you put it (the resin plate) on the plate, it sticks to it. It doesn't move from there. I wondered what I could do about that... After careful consideration, I came up with the idea of spreading a thin layer of oil on the base plate using a rag, wiping it off when it was dry, and then placing the resin plate on it and sticking it on by sliding it around. Once it is stuck, it is no longer good. Therefore, the resin plate with double-sided tape is placed on the base plate, and it is applied by shifting it around.

SMAH: The size of the original manga is often B4, and we reduce it to magazine size. As Mr. Kuroyanagi mentioned, we had never printed manga at this size before. Thank you very much for your various efforts to make this possible.

Mr. Takaoka, as you were watching Mr. Kuroyanagi applying the resin plates to the plates, you said, "Letterpress printing is a very strenuous job.” He said, "I have to keep applying force like this all the time.”

Takaoka: We use a Heidel platen (platen T-type printing press), which is smaller than this machine, and it can only fits up to B4, so even when the plates are large, they are usually A4 size. Even so, it still gets stuck and cannot be moved if you do it all at once. So, I put the pin between the plate and the resin plate, adjust it when I think, "Oh, that's good," I pull the needle out to fix it in place. But I have never worked with such a big resin plate either. I shudder just thinking about it. (Laughs)

SMAH: The solid black parts of the Press series that we've asked Mr. Kuroyanagi to print are very impressive. He made certain adjustments so that he could print solid black fills, but Mr. Takaoka tells me that his company would normally have refused such a job. (Laughs)

Takaoka: There was a high possibility that I would not be able to make it work, so if you had asked me to do it, I would have refused at first. (Laughs)

Everyone: (Laughs)

Kuroyanagi: Anyway, I was also surprised. I wasn't sure how I should apply the plate. In the old days, the designs for booklets, for example, were like small maps, and small resin plates were used for printing. I thought, "Well, I'll give it a try," so I put double-sided tape on it and placed it on top of the base, but once it's stuck on, it won't move. After that, I thought hard about it, until I came up with the method I'm using now.

SMAH: Mr. Takaoka, is there anything that you noticed was different from the letterpress printing process at the The Kazui Press?

Takaoka: Ours is a platen printing press, so it touches on the surface to print, but the cylinder-type printing press is in contact with the plate at the apex of the cylinder circle, so it's much easier to apply force than with the platen printing press. There's a reason why I don't like printing "solid fills" (printing on a homogeneous surface in solid black), which is that a platen press probably wouldn't be able to apply enough pressure. A bit of white ends up remaining on the middle of the plate. In that sense, I think a cylinder press that applies circular pressure is better, and it's the only way to make this type of job work.

Kuroyanagi: The key is to adjust the two rollers attached at the bottom. If the rollers are adjusted properly, there won't be any smudges. If you don't, the entire surface will propbably be smudged.

Takaoka: If the plate and rollers are not aligned, everything will stick. It's very difficult to control how far up the track the rollers should be so that they are barely touching.

Kuroyanagi: That's right. In the morning the rollers are cold, so you can adjust the ink, but if you've been working all day, the rollers will have gradually warmed up and expanded. When this happens, white areas appear under the solid surface, and ink sticks to areas where it shouldn't. So, first thing in the afternoon, the rollers are cooled down and the ink is adjusted. So we have to readjust the rollers first thing in the afternoon.

SMAH: Are certain seasons better or worse?

Kuroyanagi: For printing, in terms of the ink, winter is not a good season.

Takaoka: It's because the temperatures are low and the air is dry.

Kuroyanagi: But the rollers are more stable in the winter.

SMAH: For works with many delicate lines, you wipe the plate every time you print, don't you?

Kuroyanagi: That's right. We do that precisely because we're using a printing press. It's much easier to clean when you're offset printing. With a printing press, even a small speck of lint on the roller will cause white areas to appear in the solid black. That resin plate is just too big...

Everyone: (Laughs)

Continued in Volume 2

(Composition: Aya Okamura Photo & Movie by Toyokazu Fujita / HIORYES Inc.)